Bitumen railcar unloading systems From 1500000 ₽

Installation and commissioning are carried out by the specialists of Promservis LLC within 3 days

Calculate the price

Krasnodar

Актау

Алматы

Артём

Астана

Astrakhan

Благовещенск

Vladivostok

Volgograd

Voronezh region

Ekaterinburg

Железнодорожный

Зеленоград

Ижевск

Иркутск

Kazan

Kemerovo

Киров

Krasnoyarsk

Курган

Курск

Липецк

Магадан

Москва

Moscow region

Naberezhnye Chelny

Находка

Nizhny Novgorod Region

Omsk

Perm

Петропавловск-Камчатский

Rostov region

Самара

Saratov

Тверь

Tyumen

Udmurtia

Уссурийск

Ufa

Khabarovsk

Chelyabinsk

Южно-Сахалинск

Якутск

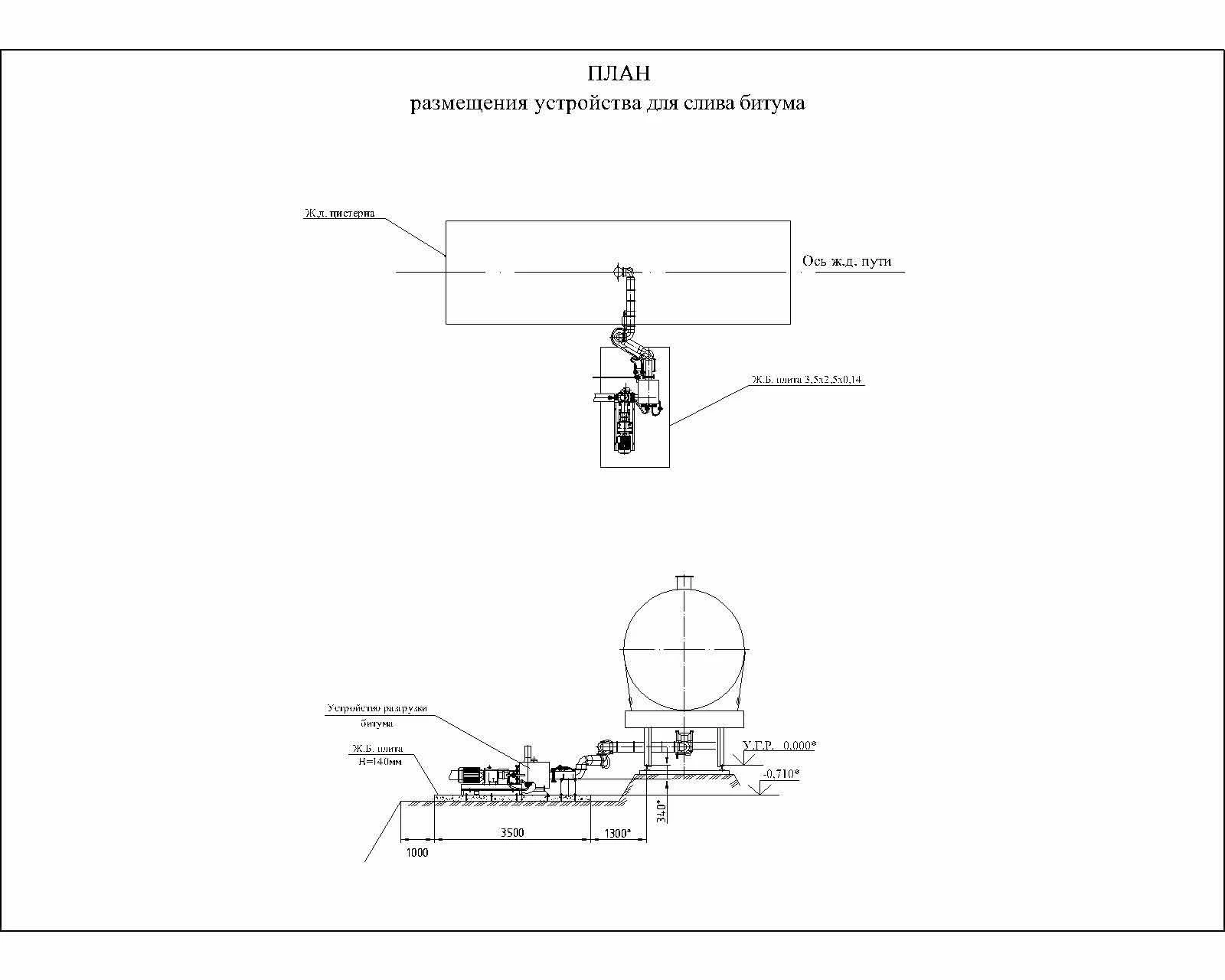

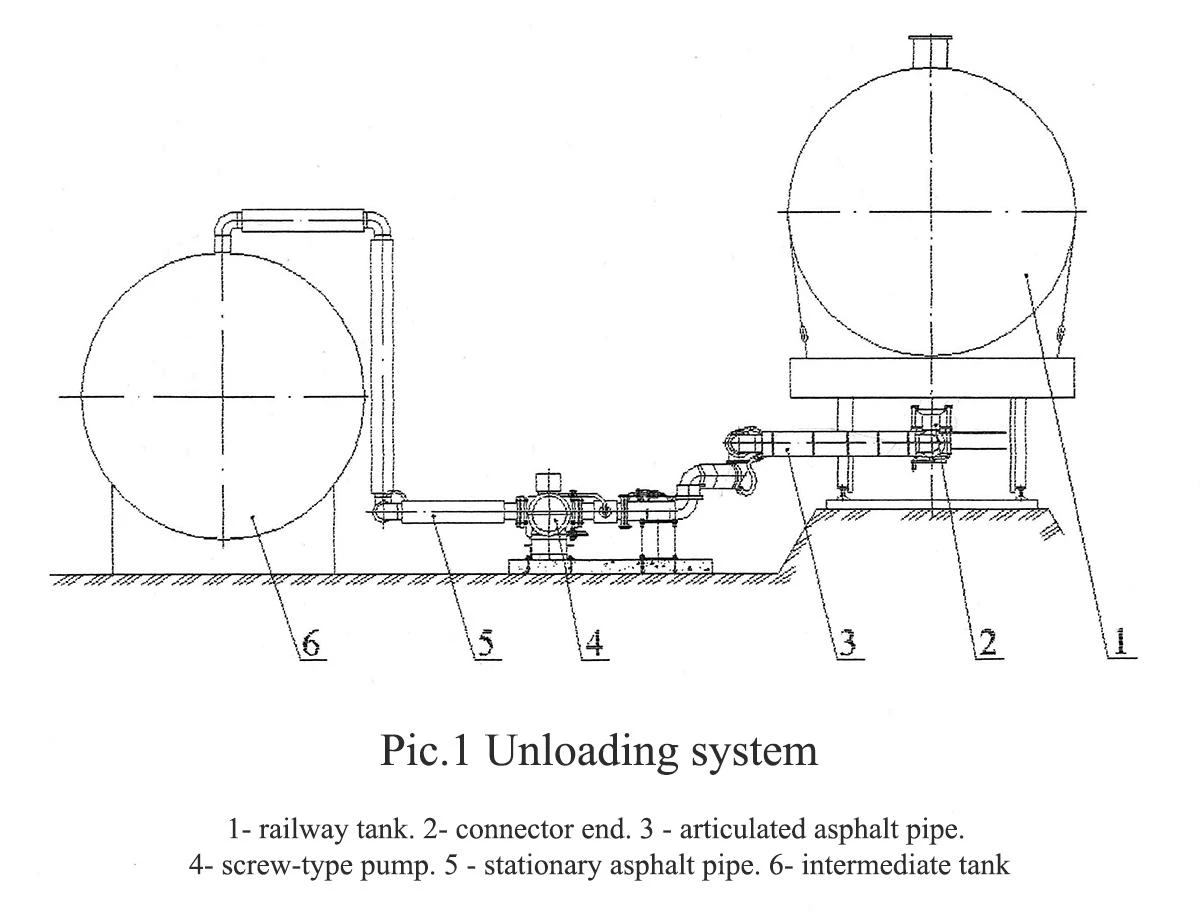

The system is designed for unloading bitumen ad other viscous oil products from railcars.

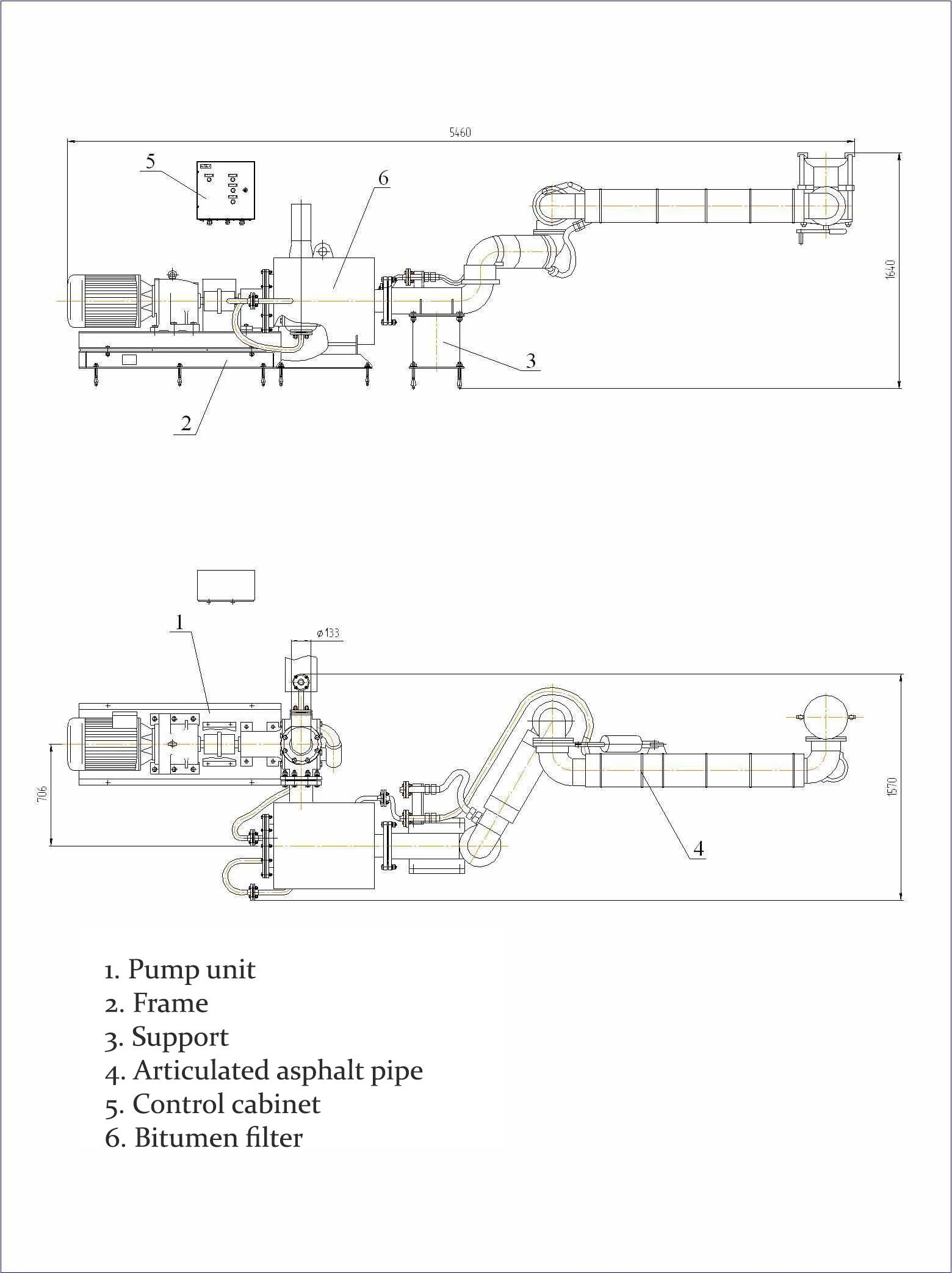

The system consists of a pump unit, including a frame, pump, drive, coupling with a cover, bitumen filter, articulated asphalt pipe interconnected with flanges, as well as a support and control cabinet with a stand. Metal hoses are used to lead the heat carrier to moving parts. Two hoses are connected with a connecting piece. The pipe is used to connect the heating jackets of the bitumen filter and the pump.

|

Pumped medium |

bitumen, viscous oil-products |

|

Pumped medium operating temperature, °С |

at least 70 |

|

Capacity, m3/h |

up to 35 |

|

Drive power, kW |

18,5 |

|

Exit flange, Du; mm |

125 |

|

Heating with heat-transfer oil, brand |

АМТ300 |

|

Heat carrier operating temperature, °С |

180 |

|

Overall dimensions: |

|

|

Length, mm |

5 460 |

|

Width, mm |

1 570 |

|

Height, mm |

1 640 |